Tree Cabling

Published June 27, 2011, By STEVE HOUSER

A tree with a deep “U” shaped fork is much stronger than one with the “V” shaped fork shown below. All photos courtesy of Steve Houser.

The angles that exist between two or more limbs which join to form a fork in the tree, or crotch, can be either strong, moderately weak or subject to structural failure (splitting or breaking). In general, limbs with a wider angle of attachment or that have a deep “U” shape will tend to be stronger than limbs with a narrow angle of attachment or a “V” shape fork.

This tight "V" shaped fork exhibits cracking.

Often, limbs with narrow angles of attachment may be cabled together to help reduce the likelihood of structural failure. Cabling allows two or more limbs to support each other rather than moving independently. However, not all limbs contain the correct angles for proper cable installation. Assuming a proper angle exists, installing a cable between two limbs helps to reduce the probability of structural failure, but cabling is not a guarantee against breakage. Trees can fail structurally, regardless of any cabling or bracing installed to reduce the odds of failure. Severe winds or snow and ice accumulation on limbs are examples of weather events that will cause excessive stress on the structure of the tree which, may lead to failure.

Multi-trunked shade trees can also fail structurally when one of the trunks either uproots or splits from the other trunks. With multi-trunked trees, each trunk does not have room to grow roots in all directions, leaving them prone to uproot. One stem is a gem—while more may leave the prospects grim. In some cases, cabling can help reduce the odds of failure.

An uprooted multi-trunk tree.

Cabling installation techniques and materials are tree specific, but the following standards cover most common situations.

- As a rule, cables are installed at around two-thirds the height of a tree.

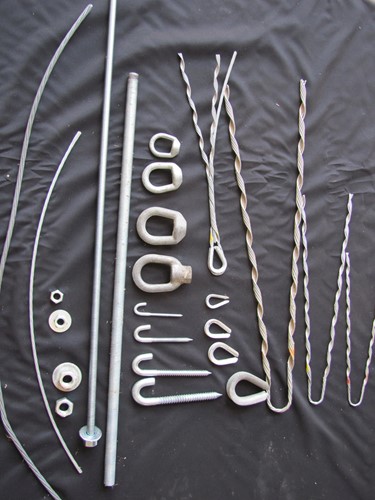

- Cabling materials must meet tree care industry standards. Hardware or home improvement businesses do not stock materials with a high enough strength rating to use in trees.

- Industry cables are designed for extra high strength. They typically range from one-eighth inch to one-half inch diameter. The diameter of limbs to be cabled, as well as the size of the tree, will determine the size of cable required.

- In small to medium sized limbs, cables are attached to the tree with a “J” lag, or lag hook. Lag hook sizes range from one-quarter inch to five-eigths inch. For large limbs, a threaded rod is placed through the tree limb. An “amon eye”, which actually holds the cable, is attached to the rod. Both types of hardware require drilling into the tree, which is not ideal—however, it beats losing a major limb.

- The cable is typically attached to the amon eye or lag hook using a thimble and dead-end wrap.

- The cable tension must be correct for the particular application, so a “come along” winch is often used to provide the tension between the limbs.

A cable and lag hook installed.

An assortment of cabling supplies.